Because they are such specialized power tool accessories, most woodworkers and tool users know what they're getting into when shopping for a new dado set. But there are still a few factors and guidelines to cover that will make shopping for a new dado set much easier.

Because they are such specialized power tool accessories, most woodworkers and tool users know what they're getting into when shopping for a new dado set. But there are still a few factors and guidelines to cover that will make shopping for a new dado set much easier.

Whether you're new to using dado blade sets or a seasoned veteran, the dado set information in this article will help guide you to a solid purchase.

Dado Set Types

There are two major types of dado sets: "stacked," and "wobble."

"Stacked" and "wobble" dado systems differ greatly, including in the quality (flatness/squareness) of their cuts.

Since dado blades are designed to cut grooves for tight-fitting, precise woodworking joints, shoppers should focus on getting a set that will produces the best "flat-bottom" (or "square-bottom") cuts possible.

Dado grooves can also be cut at different widths, and the two different dado systems adjust between different widths in completely different ways.

The majority of dado cuts made are between the widths of 1/4" and 15/16" in increments of 1/16".

Stacked Dado Sets

Stacked or "stack" dado sets outperform wobble dado blades in every way, but they are more expensive. Stacked dado sets achieve their cutting width by stacking several cutting blades side by side.

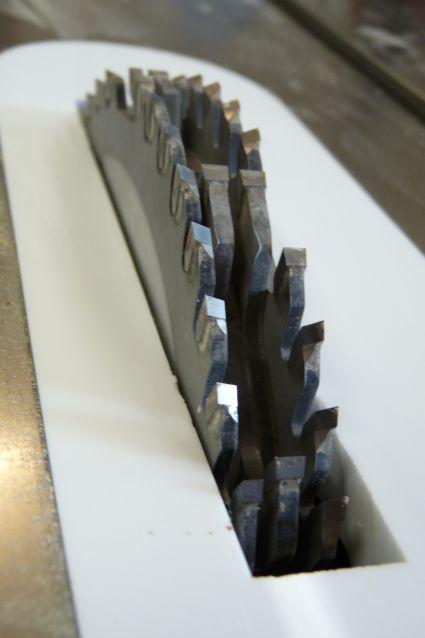

There are two kinds of dado blades included in stacked dado sets: outer blades, and chippers.

There are two kinds of dado blades included in stacked dado sets: outer blades, and chippers.

- Outer dado blades resemble (and cut like) standard saw blades. They typically have between 18 and 40 cutting teeth. Their higher tooth density (TPI) and positions on the outsides of the set are what produce a dado groove's sharp, clean edges.

- Inner dado blades, or "chippers," fill in the space between outer blades. They typically only have between 2 and 4 cutting teeth.

This extremely low tooth count means that chippers cut more coarsely than outer blades, as their principal job is to simply remove material in the center of the dado groove.

Because of their low tooth count, chippers are often manufactured in non-circular shapes to reduce material costs.

Higher quality (more expensive) stacked dado sets will include completely round ("full plate") chipper blades like the one pictured above, but such heavy-duty blades should only be used on powerful cabinet saws. As can be seen, heavy duty chippers can also have a few more cutting teeth than the average chipper.

Most stacked dado sets include 2 outer blades and 4 to 6 cutters. One of the cutters included in the set is usually 1/16" wide in order for the dado groove width to be adjustable in increments of 1/16", while the other blades in the set are usually 1/8" wide.

Special dado "shims" are also included with stacked dado sets (depending on the set) that allow width adjustment without changing the number of blades installed.

It is especially important to make sure that stacked dado blades are very clean when installing them. Small amounts of dust and particles between blades can significantly affect the cutting width of the set.

[Back to top]

Wobble Dado Blades

Wobble dado blades are not "sets," since only one blade is used in the system. Instead of stacking a number of blades to achieve the desired cut width, wobble dado blades use a different method.

A single wobble blade is installed along with an "hub"that can be adjusted to different angles. As the angled blade spins, it crosses over the adjusted width of the cut in the course of turning around its full circumference.

Wobble blades are much less expensive than stacked dado sets because only one blade is needed, but they come with a list of serious disadvantages:

- Wobble blades make less accurate cuts. A good, flat-bottom, squared groove is difficult or impossible to produce from a wobble blade.

- Some users report that using wobble blades can be dangerous.

- Because their design causes additional vibration, wobble blades can be damaging to the saws with which they are used, often shaking fasteners and other parts loose.

Dado Set Compatibility

Compatibility considerations for dado sets are minimal, because there are relatively fewer variations in dado blades when compared to other saw blade types.

We cover three areas of compatibility below that match dado sets to their saws and application materials.

Saw Blade Specification Guidelines

We cover three areas of compatibility below that match dado sets to their saws and application materials.

Saw Blade Specification Guidelines

When it comes to matching dado blade specifications (like TPI, hook angle, and blade material) to an application, shoppers can confidently follow guidelines for standard saw blade application matching.

Generally, higher TPI (teeth per inch) blades are best for harder materials, and materials that tend to chip, like plywood and melamine. More teeth mean a finer, slower cut, and less teeth mean a faster, rougher cut.

Most dado blades are designed with a 0° hook angle, and are intended for use on table saws. Dado blades with negative hook angles (most commonly -12° and -5°) are for use with radial arm saws.

Like other saw blades, dado blades are manufactured from a variety of materials (like carbon steel, high speed steel, and carbide) that affect what materials they can cut and how durable they are.

For additional information about how to match saw blade specifications to an application, take a look at this Saw Blades 101 article.

[Back to top]

Arbor Hole Compatibility

We only mention arbor hole compatibility for dado blades here to point out that it is almost never a compatibility issue, as it is more commonly with other saw blade types.

Only the largest, industrial sized dado blades will have a larger arbor hole, and you'll know ahead of time if that's the kind of blade you need.

Almost all dado blade arbor holes are the standard 5/8" diameter.

[Back to top]

Blade Diameter and Saw Power

It is very important to match dado blade diameter to a saw that has sufficient power to operate it. This is the most crucial compatibility consideration regarding dado sets.

Dado blades are available in two diameter sizes, 6" and 8". Larger 8" blades allow for deeper cuts.

Generally, there are three major sizes of table/radial arm saws available: portable/bench saws, contractor saws, and cabinet saws.

Here are the guidelines for matching blade diameter to the size (power) of the saw:

Portable/Bench Saws-

Only use 6" diameter blades. These saws will not have the necessary power to correctly operate 8" blades .

Contractor Saws-

Both 6" and 8" diameter blades can be used, but 8" blades with "full plate" chippers should not be used on contractor saws, because the extra material makes them much more heavy.

In other words, if you're planning to use an 8" diameter set on a contractor saw, make sure that the chippers are not completely circular.

Cabinet Saws-

Both 6" and 8" dado blades can be used on cabinet saws, including sets with "full plate" chippers.

[Back to top]

Dado Sets and Insert Plates

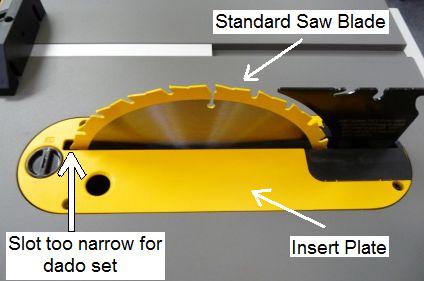

A typical table saw is pictured below with a standard saw blade installed (not a dado set). The yellow plate through which the blade is protruding is called an insert plate.

The insert plate installed on the above table saw is a standard type made to accommodate standard saw blades, and as can be seen, its slot would be too narrow for a dado set.

These means that using a dado blade set with a table saw also means buying and installing a customized insert plate. Shoppers have two dado insert plate options:

1. A standard dado insert plate with a pre-cut blade slot can be used. Each insert plate should be sized to the width of the dado grooves being cut, meaning that a different insert plate is needed for each dado groove width.

2. A zero clearance insert plate can be used. Zero clearance insert plates do not have pre-cut blade slots. Users must use the dado blade to cut the opening in the plate by first installing the plate (with the blades lowered all the way down), and then slowly raising the blades (in operation) through the bottom of the plate.

So why all that hassle? When done correctly, the blade opening in the insert plate will match the dado set's width exactly.

By eliminated the gaps on either side of the blade, sawdust and other debris is prevented from jamming up the blades' operation. This greatly reduces the chance of tear-out when making dado cuts. This kind of upgrade is important for very precise woodworking cuts like dado grooves.

[Back to top]

Conclusion

Dado sets are another power tool accessory stocked here at eReplacementParts.com's online warehouse of tool and machine parts. Visit our Dado Sets page to browse our selection of stacked dado sets.

Making tool and power tool accessory purchases that return their value is only a matter of having the right information. And sometimes, getting the right information is just a matter of knowing where to look.

We at eReplacementParts.com go the extra mile to put customer-empowering information tools all in one place, here at our professional parts warehouse.

[Back to top]

What we're about.