Porter Cable Parts

We sell only genuine Porter Cable ® parts.

Trusted Partner ?

Search By Model or Part Number

or

Popular Porter Cable Product Types See All

Popular Porter Cable Parts

This is an original part from Craftsman for nailers and staplers. This part produces air pressure to force the driver in the direction of the fastener. You will need a allen wrench set, adjustable wrench and a screwdriver to replace this part. This part is made of plastic and sold individually.

Genuine Porter Cable replacement partIncludes 1 Carbon Brush with wire lead attached.• Worn brushes are often the cause of a poorly running motor • Replacing brushes can fix an intermittent motor • New brushes can restore a motor’s electric braking Carbon motor brushes are one of the most commonly replaced power tool components. Because carbon brushes are wear items, meaning that thr...

This cord is a genuine DeWalt replacement part. This cord is compatible with the list of models below. This part is made for double insulated tools It is a two wire cord with two prongs and does not need a ground wire. The cord is sold individually. Installation of this part requires the new cord wires to go correctly into wire terminals also routing the cord and wires in the right path can help a...

The 151281-08 Pad is used to hold 5 inch Hook and Loop sandpaper with 8 vacuum holes. Over the past few years the popularity of Hook and Loop paper has grown because of the ease of changing sandpaper when needed. Over that of the PSA (Pressure Sensitive Sandpaper)Applying too much pressure on the sander may cause premature wear on the Hook and Loop pad.When a pad needs to be replaced, simply remov...

This is a Genuine OEM replacement part It is sold individually Two tires are needed on the Bandsaw.If one tire is worn, it is advisable to replace both at the same time.The purpose of the Blade Pulley Tire is to keep the blade tracking correctly. Over time they will become brittle or stretched out. You then will have the problem of the blade coming off the pulleys or not tracking properly. The tir...

This brush is a genuine Porter-Cable replacement part, not generic. As pictured, this brush is ready to install and includes carbon brush, wire lead, and spring. This item is sold individually. Over time, brushes will wear down and eventually require replacement. This brush will fit the models listed in the 'Compatibility' section below. It is not guaranteed to fit any other power tool models.•...

Genuine OEM replacement part, this item is sold individually. The purpose of this part is to keep air pressure in the cylinder of the tools listed below.If you have an air leak in your pneumatic tool it is a good practice to replace the O-ring and seals.

This Ball Bearing is sealed on both sides. It is a genuine DeWalt replacement part and is sold individually.Ball bearings are used to reduce friction between rotating parts.. The balls or rollers take the load and spin, distributing the weight evenly while the minimal contact area of the ball reduces friction. This reduces wear on the tool and allows it to run smoothly.Bearings experience constan...

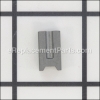

This is a genuine Porter Cable replacement part, it is sold individually.The purpose of the 890725 Retainer is to secure the pins used on the model numbers shown below.It is advised to check the condition of the retainer often, for the reason the do deteriorate over time and can fall off of the pin they are retaining.

When you use a compressor the air that is compressed inside the tank will condensate and leave water inside the tank.If it is left in the tank too long it can start to rust out the inside of the tank.The Drain Valve should be opened up and let the water drain out. The water will build up if you have a tendency to leave air in your tank for a long period of time.You should drain your tank after eac...

This carbon brush is an authentic DeWalt replacement part.It is sold individually, 2 are needed to make a set• Worn brushes are frequently the cause of a poorly running motor.• Replacing brushes can fix an intermittently operating motor.• New brushes can restore a motor’s electric braking.Carbon motor brushes are one of the most commonly replaced power tool parts. The reason is that carbon...

Popular Porter Cable Models

All Porter Cable Product Types

Porter Cable Air Tool Parts

Porter Cable Band Saw Parts

Porter Cable Charger Parts

Porter Cable Chop Saw Parts

Porter Cable Circular Saw Parts

Porter Cable Coil Nailer Parts

Porter Cable Compressor Parts

Porter Cable Cordless Drill Parts

Porter Cable Electric Drill Parts

Porter Cable Finish Nailer Parts

Porter Cable Framing Nailer Parts

Porter Cable Generator Parts

Porter Cable Grass Trimmer Parts

Porter Cable Grinder Parts

Porter Cable Hammer Drill Parts

Porter Cable Heat Gun Parts

Porter Cable Impact Driver Parts

Porter Cable Impact Wrench Parts

Porter Cable Jig Saw Parts

Porter Cable Laminate Trimmer Parts

Porter Cable Misc Parts

Porter Cable Misc Saw Parts

Porter Cable Misc Tool Parts

Porter Cable Miter Saw Parts

Porter Cable Nibbler Parts

Porter Cable Painting Tools Parts

Porter Cable Planer Parts

Porter Cable Plate Joiner Parts

Porter Cable Pressure Washer Parts

Porter Cable Reciprocating Saw Parts

Porter Cable Router Parts

Porter Cable Sander / Polisher Parts

Porter Cable Screwdriver Parts

Porter Cable Stapler Parts

Porter Cable Table Saw Parts

Porter Cable Vacuum Parts

Power Tool Parts Repair Articles

Same Day Shipping

Toll Free Support

Repair Help & Videos

How Are We Doing?

I just wanted to thank you for the great video on how to repair a Porter-Cable router. I broke the spindle pin on my router and had to disassemble it to get the chuck off. Your video was exactly what I needed to make the repair. It took a while, but seeing what had to be done before completing the project was priceless Thanks again.

Willet

New Hampshire, USA

eReplacementParts is proud to be the Preferred Partner of dozens of leading equipment brands that build the gear you love. That means our inventory and availability are unmatched, and in some cases, we are the exclusive parts providers for these brands for their OEM parts programs.